Robotic Manipulation and Mobility Laboratory

Columbia University, New York, NY

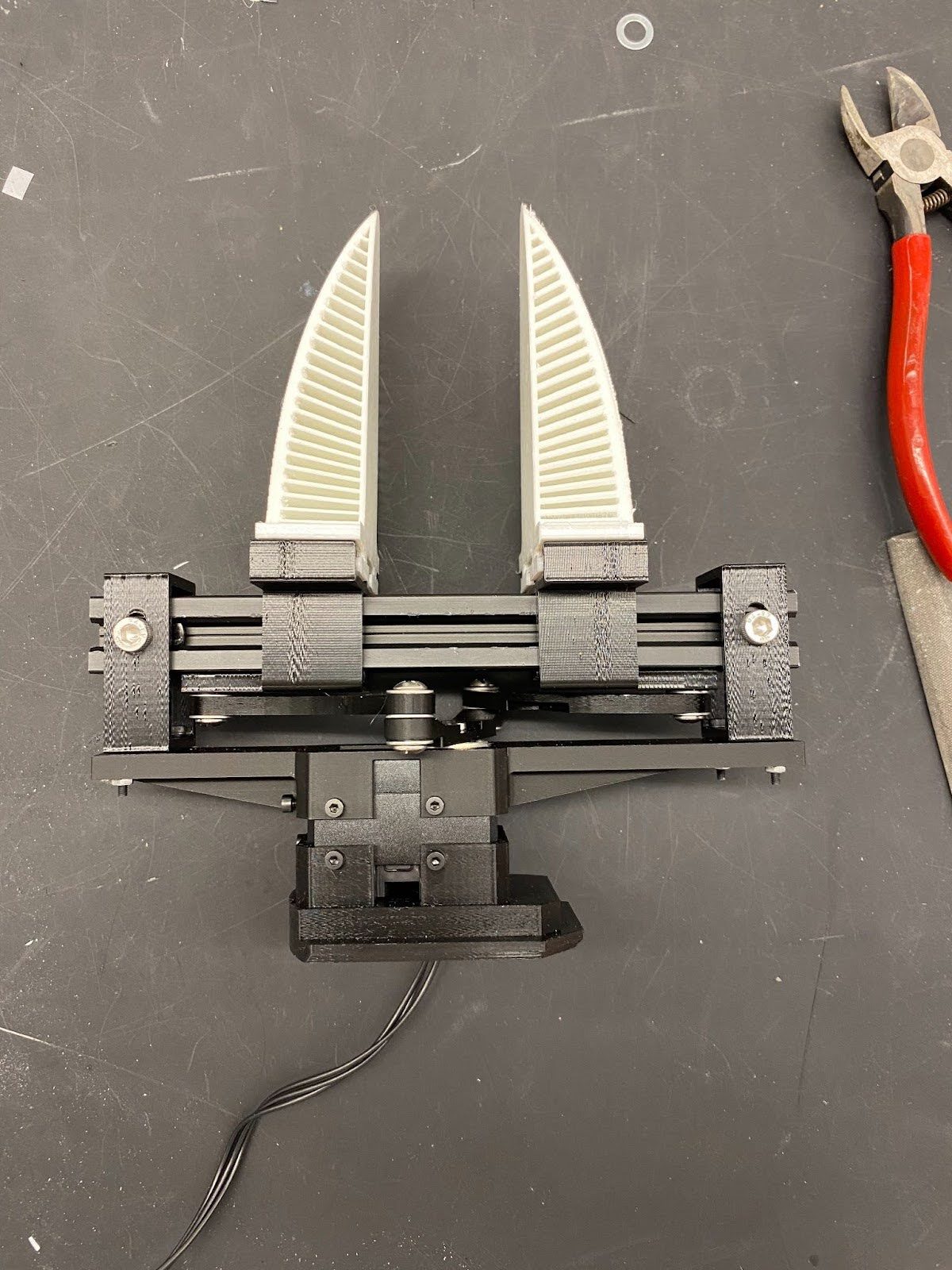

I spent a few months working on developing a robotic end effector and paired human controller as a contribution to the development of a larger bimanual teleoperation station. The gripper/controller system maps 1:1, allowing the human user to directly mimic the grasping and manipulation of objects. We intend to use the low-cost design to conduct research into robotic ability to mimic dexterous tasks.

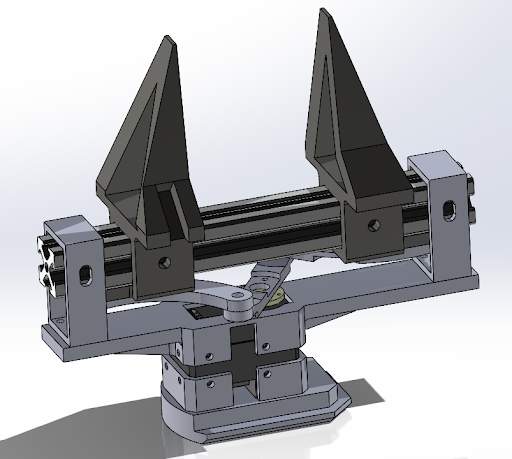

Both the gripper (end effector) and controller (human-operated “tongs”) are simple linear graspers, and draw heavy inspiration from previous ALOHA work. They have the same range of motion and identical grasping proportions.

Some of the primary design focuses included:

Finger Design

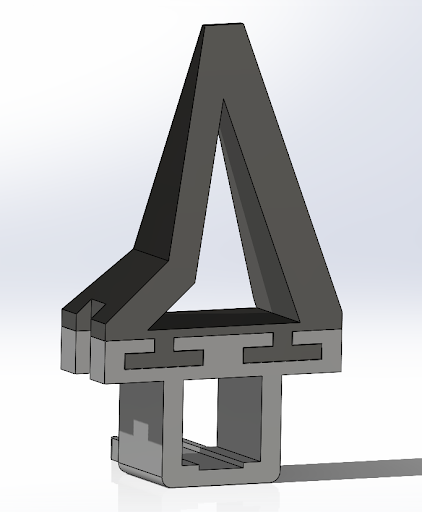

The “fingers” of the end effector are versatile and easily swapped, allowing for application to a variety of tasks. For this project, two versions were 3D printed: a standard PLA option and a more flexible TPU option.

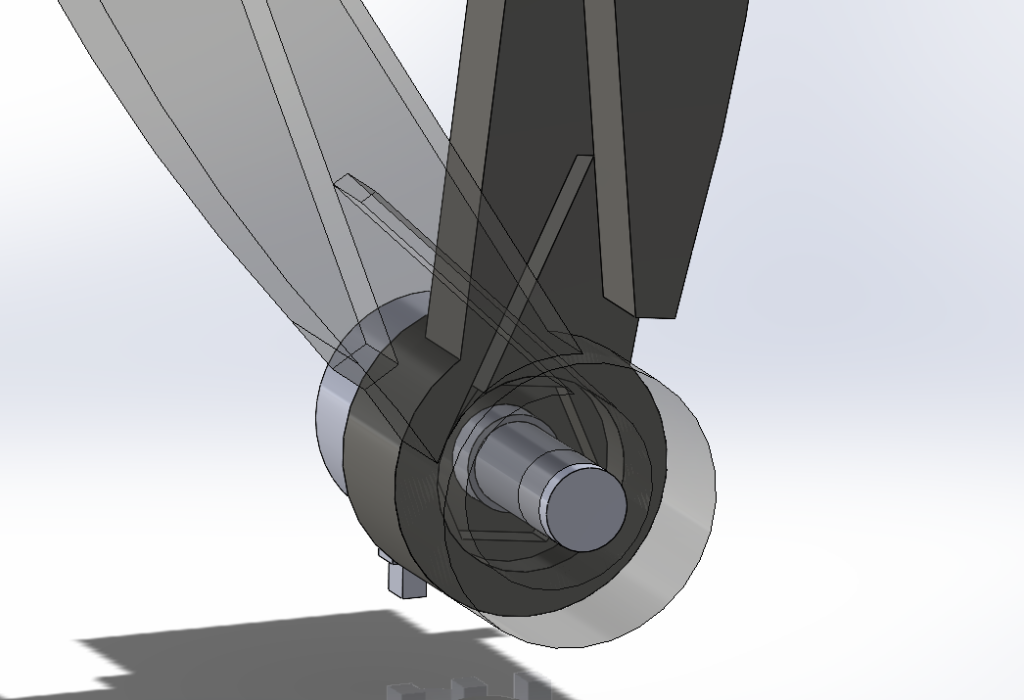

End-Effector Linkages

To translate the rotational motion of the motor to linear gripper motion in an efficient way, we designed a torque-optimized linkage system connecting the fingers of the gripper to the motor.

Motion Mapping

The open/close motion of the gripper is mapped from the controller to the end effector using a fine-grain 1-turn potentiometer embedded in the base of the former. For this project, mapping was done over serial between the arduino boards controlling the respective components. However, preliminary work was also done in ROS for future iterations.

Ergonomics

Much focus was given to the human interface itself, which feels like a pair of kitchen tongs and can be manipulated using one hand. A torsional spring, also embedded in the base, provides resistive feedback that allows for easy task mapping.